Brace yourself, California wine lovers. The price of your beloved wines are likely to be rising soon.

Under new legislation passed by the California State Water Resources Control Board in January, approximately 1,500 vineyards and wineries will face increased production costs in order to comply with wastewater

monitoring requirements. What do the additional costs of water monitoring mean for Californian wine drinkers? It means that production costs for wine will be raising, and that will likely result in an increase in the average cost of a bottle of wine.

monitoring requirements. What do the additional costs of water monitoring mean for Californian wine drinkers? It means that production costs for wine will be raising, and that will likely result in an increase in the average cost of a bottle of wine.

The exact costs associated with the new state regulations for wastewater management will vary, depending on that size and production of the winery. The estimated costs are high — up to as much as $180,000 annually, according to one Sebastopol winery.

A Natural, Inexpensive Wastewater Management Option

Fortunately, Aquabella Organic Solutions (the parent company to Unleash Organics), is already providing several state wineries with a significantly less expensive option for wastewater management.

As it stands now, the financial investments needed to comply with new legislation are going to have a significant impact on wineries of all sizes. The smallest wineries are facing a cost of $500 for monitoring equipment, while the expense for medium to larger wineries ranges from $5,750 to $45,750 — according to the State Water Board’s General Waste Discharge Requirements for Winery Process Water. Even more shocking, those figures do not include the additional cost for in-house and consultant monitoring services, which could cost between $8,000 to $180,000!

In comparison, the cost to use Aquabella Organics’ Bio-Enzyme for wastewater treatment is only 10% of the proposed costs in the Water Board’s General Waste Discharge Requirements draft. The product has a proven track record for handling winery wastewater, having already been used by several California wineries in the past couple years.

Based on winery process water volumes, this side-by-side comparison shows financial investment for installing monitoring equipment vs. using Aquabella’s Bio-Enzyme solution shows how much money wineries will spend on each compliance option:

Based on winery process water volumes, this side-by-side comparison shows financial investment for installing monitoring equipment vs. using Aquabella’s Bio-Enzyme solution shows how much money wineries will spend on each compliance option:

Standard Wastewater Monitoring Equipment vs. Aquabella Bio-Enzyme

- Tier 1 – Standard Monitoring Equipment: $500 vs. using Aquabella Bio-Enzyme: $30

- Tier 2 – Standard Monitoring Equipment: $5,750 vs. using Aquabella Bio-Enzyme: $300

- Tier 3 – Standard Monitoring Equipment: $10,750 vs. using Aquabella Bio-Enzyme: $1,000

- Tier 4 – Standard Monitoring Equipment: $45,750 vs. using Aquabella Bio-Enzyme: $15,000

Not only does Aquabella’s Bio-Enzyme solution offer vineyard managers a significantly less expensive wastewater solution, it also prevents the need to build a costly full water treatment facility for wastewater that is only used for three (or fewer) months of the year. Every vineyard manager knows that one of the defining characteristics of process water is the seasonal nature of it. Most of the process water is generated during “crush,” when grapes are harvested and pressed–generally from September through November.

When used during the three months of crush, Aquabella Bio-Enzyme enables wineries to significantly shorten the timeline required for nitrogen, Biochemical Oxygen Demand (BOD), and organic matter treatment, which allows for a higher volume of wastewater to be processed more rapidly.

Amid new legislation that will financially impact every California winery, Aquabella Organics offers a low-cost alternative to expensive wastewater monitoring solutions suggested in the State Water Board General Waste Discharge Requirements for Winery Process Water. By lowering the financial investment necessary to comply with process water requirements, Aquabella’s Bio-Enzyme could help wineries minimize the rise in production costs, and ultimately the cost of a bottle of California wine!

The Science Behind Aquabella’s Wastewater Management Solution

Vineyard process water is wastewater that is generated from a wine – or juice – making processes. It includes water used during harvest, cleaning, crush, bottling, wash, and various other activities. Under new legislation passed by the California State Water Resources Control Board this January, approximately 1,500 vineyards and wineries that generate more than 10,000 gallons of vineyard process water have to actively monitor and, if necessary, treat before application onto vineyard soil.

Land application is a common reuse of this water which helps keep costs down, especially for smaller vineyards. Importantly, these new regulations also mean larger vineyards – those that generate greater than 1 million gallons of process water per year – will have to demonstrate that they are not impacting the local groundwater by actively monitoring groundwater quality as well as process water effluent quality.

One of the defining characteristics of process water is the seasonal nature of it, with large amounts being generated during “crush”, when grapes are harvested and pressed– generally from September through November. Building a full water treatment facility for wastewater that is [only present] three or fewer months of the year is an expensive option that may be financially out of reach – especially for smaller vineyards. The main contaminants in vineyard process water subject to regulation are nitrogen, salinity, and contaminants that affect dissolved oxygen (DO) levels – primarily organic matter, with Biochemical Oxygen Demand (BOD) levels serving as an indicator for this. Wine, grape juice, grape solids or pomace, and cleaning chemicals in the crush wastewater results in high contaminant levels.

One of the defining characteristics of process water is the seasonal nature of it, with large amounts being generated during “crush”, when grapes are harvested and pressed– generally from September through November. Building a full water treatment facility for wastewater that is [only present] three or fewer months of the year is an expensive option that may be financially out of reach – especially for smaller vineyards. The main contaminants in vineyard process water subject to regulation are nitrogen, salinity, and contaminants that affect dissolved oxygen (DO) levels – primarily organic matter, with Biochemical Oxygen Demand (BOD) levels serving as an indicator for this. Wine, grape juice, grape solids or pomace, and cleaning chemicals in the crush wastewater results in high contaminant levels.

While there are various treatment options available for vineyards, one of the more common is the use of a treatment pond or a series of treatment ponds. This is a pond in which the process water can be treated until the required water quality metrics are met. Common treatment practices in these ponds include the separation of solids from the water by settling to the pond bottom, pond aeration increasing oxygen levels by mixing air into the water], and cycling pond water between aeration and anaerobicity (low oxygen levels). The presence/absence of oxygen is meant to create conditions that improve microbial degradation of various contaminants. Problems occur when the existing pond system is no longer able to treat process water fast enough to allow for land application before new process water is generated, or when solids accumulate reducing pond capacity and requiring excavation.

A low-cost treatment option which works without having to build on or improve existing water treatment infrastructure that is able to significantly shorten the timeline required for nitrogen, BOD, and organic matter treatment – allowing a higher volume of wastewater to be processed more rapidly – [is of interest to] California state winemakers. AquaBella Bio-Enzyme is a microbe-based water treatment product that can rapidly improve wastewater quality without [the need] for further expensive [equipment]. AquaBella is made by the Sebastopol-based company AquaBella Organic Solutions, which has been making microbe-based products that improve water quality and soil fertility for over 10 years. It is easy to apply, requiring no special equipment, and can work in a wide range of pH and salinity conditions.

Aquabella Treatment of a Vineyard Process Water Pond

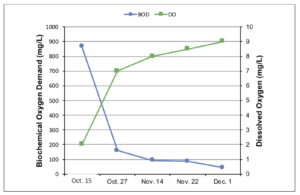

Process water organic matter contamination can cause several water quality issues including pond solids accumulation, odors, anaerobicity (as indicated by low Dissolved Oxygen -DO levels), and salinity (as indicated by Volatile Dissolved Solid levels). BOD is used by California as an indicator to measure this contaminant. AquaBella Bio-Enzyme can rapidly break down and remove organic matter in process water resulting in improved DO, reduced BOD and VDS and controlling odors. Figure 1 shows AquaBella-treated vineyard process water. AquaBella treatment occurred on Oct. 15 when BOD was over 850 mg/L, by Oct. 27 BOD was at 160 mg/L, and by Dec. 1 was at 43 mg/L, with an improvement in DO levels also seen. AquaBella Bio-Enzyme can also significantly reduce organic solids accumulation in process ponds, avoiding excavation.

Process water nitrogen contamination is mostly present as ammonia and organic nitrogen. AquaBella Bio-Enzyme can rapidly remove nitrogen from process water by (1) releasing nitrogen from organic matter; (2) catalyzing the chemical conversion of ammonia to nitrate in a process called “nitrification”, and finally (3) catalyzing the chemical conversion of nitrate into dinitrogen gas. Nitrogen gas will then bubble out from the water into the atmosphere [without causing any further problems].

As mentioned above, AquaBella Bio-Enzyme is very easy to apply. It is sold as a liquid microbe concentrate, and doesn’t need any activation to work. Process water should be between pH 5-8.5, and salinity will not affect activity. Treatment is 1 gallon AquaBella per 500,000 gallons of water, with a second application recommended after 1-2 weeks for high contaminant levels.

Please contact Aquabella Organics for more information on Bio-Enzyme for your wastewater management needs!

If you are looking for products to optimize your plants’ growth potential, please visit the Unleash Root Inoculant or BioFilm Buster Pro product pages or contact us directly with questions!